Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

With the rapid development of smart industry, more and more manual operations on our bodies have slowly turned into mechanical operations. So what are the robotic arms we share? Which parts of our robot arms are used in the electrical industry?

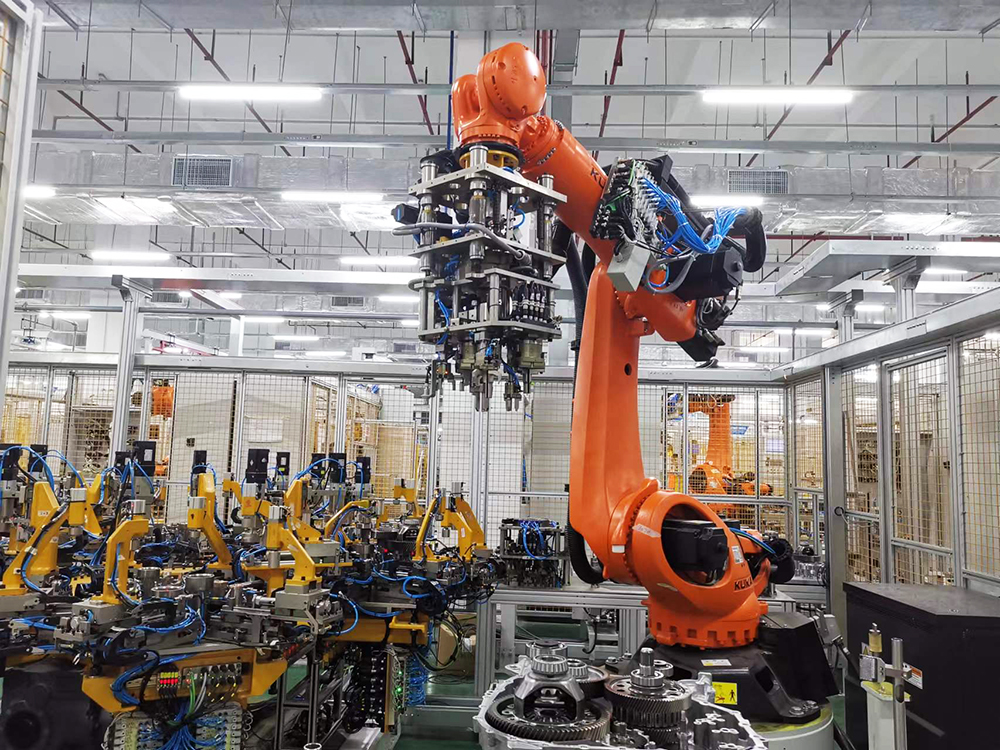

As shown in the picture, there is Distribution System on the robot arm to facilitate on-site wiring. A breakout box bundles multiple cables into one main cable that connects to the controller. Distribution box is equipped with a status indicator light to facilitate users to observe the signal status at any time. It plays an important role in the connection of distribution cables or optical cables to subscriber lines and branch trunk lines. The junction box can be installed in narrow spaces such as bridges, boxes, pipes, cable trenches, etc. It does not occupy the effective usable area of the building and is easy to install without cutting the main cable.

There are also a lot of Connection Cable on the robot arm.Cables can be divided into power cables, communication cables and control cables according to their uses. Compared with overhead lines, the advantages of cables are small insulation distance between lines, small space required, underground laying, no need for above-ground space, not affected by environmental pollution in the area, high power transmission reliability, and does not affect personal safety. and surrounding environment. small. But the cost is high, construction and maintenance are complicated, and manufacturing is also complex. Therefore, cables are mainly used in densely populated, grid-connected areas, as well as densely populated, busy areas. When laying across rivers, on rivers, or on the seabed, the use of long-span overhead lines can be omitted. Cables may also be used where interference from overhead line communications must be avoided, aesthetics must function, or dangers from targets must be avoided.

In order to better adapt to the industrial robot arm, we choose different types of suitable connectors. Connectors are an indispensable part of electronic equipment. If you follow the path of the current flow, you will always find one or more connections. Connector shapes and structures are constantly changing. Depending on the application object, frequency, power, application environment, etc., connectors have different forms. But no matter what type of plug it is, it must ensure that the current flows smoothly, continuously and reliably. Generally speaking, what a connector connects is not limited to electrical current. Nowadays, with the rapid development of optoelectronic technology, light has become the signal carrier in optical fiber systems. Glass and plastic have replaced wires in ordinary circuits, but optical signal connectors are also used in signal paths and serve the same purpose as circuit connectors.Our company has M8 connector, M12, 7/8, M23, Rj45 Connector, Y/T, etc. Of course, our Heavy Duty Connector are also popular in many countries and regions.

Robot arms for the injection molding industry

Robotic arms in the injection molding industry are often called injection molding machine manipulators and plastic machine manipulators. It can imitate some functions of the human upper limbs and replace manual work such as automatic molds, in-mold inserts, in-mold labeling, out-mold assembly, molding, classification, and palletizing. , product packaging, mold optimization, etc. It is an automated production equipment that can automatically control its tools to deliver products or operate the production process according to predetermined requirements. The robotic arm in the injection molding industry is a machine specially equipped for automated injection molding production.It can reduce heavy physical labor, improve working conditions, and make production safer; improve the production efficiency of injection molding machines, stabilize product quality, reduce scrap rates, and reduce production costs. It plays an important role in improving the competitiveness of enterprises.

Robot arms for the punch press industry

The robotic arm in the punch press industry is also called a punch press manipulator or a punch press manipulator. It is a special robotic arm used in the punch press industry. The punching robot of the punch machine can automatically perform multiple designated actions according to the pre-selected program to realize automatic clamping and transportation of objects.

Robot arm for lathe industry

The robotic arm of the lathe industry is also known as the lathe automatic loading and unloading manipulator and the lathe loading and unloading manipulator. The lathe automatic loading and unloading manipulator mainly realizes the complete automation of the machine tool manufacturing process and adopts integrated processing technology. It is suitable for the loading and unloading of the production line, workpiece turning, and workpiece rotation.

The automatic loading and unloading manipulator for lathes is mainly used to fully automate the manufacturing process of machine tools and uses integrated processing technology. It is suitable for loading and unloading the production line, turning workpieces and turning workpieces. maintain. In domestic mechanical processing, many use special machinery or manual loading and unloading of machine tools. This is very suitable when the products are relatively simple and the production capacity is not high. However, with the progress and development of society, science and technology are advancing day by day. the use of special machinery or manual loading and unloading of machine tools has revealed many shortcomings and weaknesses.

For one thing, specialized machinery occupies a large area, has complex structures, and is cumbersome to maintain, which is not conducive to automated assembly line production. Secondly, it is not flexible enough, so it is difficult to adapt to the accelerating changes, making it difficult to adapt the product structure; secondly, the use of manual labor increases labor intensity, is prone to labor injuries and accidents, efficiency is relatively low, and the quality of products loaded and unloaded manually is not stable enough. the quality of products is not stable enough to meet the requirements of mass production.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.