Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

SVLEC IO -Link communication equipment is designed to simplify the connection of smart Sensor and smart devices on the factory floor, support the digital upgrade of industrial manufacturing, and achieve seamless communication throughout the process. With "IO-Link" technology, Sensors can better adapt to the needs of easy and quick change of parameter settings in the field. It offers great flexibility in the production process. It is the last step to actuators and sensors. It is also called the last mile technology for automation.

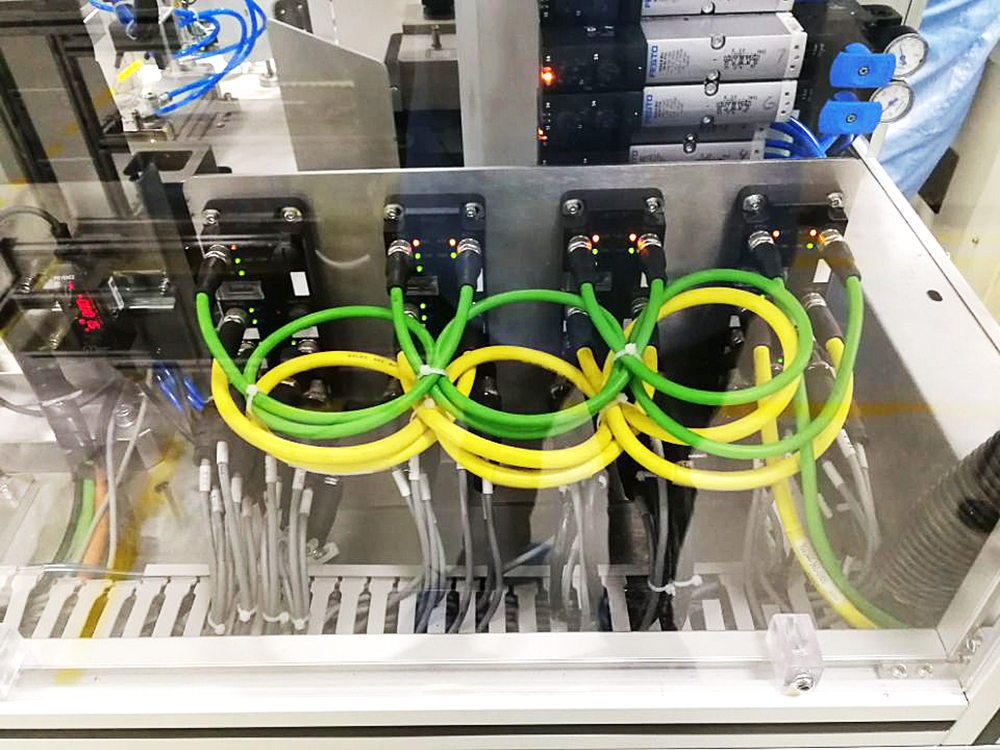

I/O System.Traditional centralized IP20 connections require large control cabinets, messy cable ducts and tedious installation. Because there are no diagnostic instructions, maintenance is difficult, and serious failures can lead to long downtimes. SVLEC's distributed IP67 IO -Link connection has a standard interface, simple wiring, open connection and easy expansion.

The master station stores data, which facilitates device replacement. It has diagnostic instructions that facilitate maintenance and troubleshooting and significantly reduce downtime. It is widely used in robotic welding fixtures, conveyor elevators, turntables and other workstations to acquire signals from sensor positions and issue instructions for cylinder actions. It can improve the performance of automated production lines, achieve efficient data acquisition and transmission, ensure secure communication, and control costs.

When used in automotive differential assembly lines, it not only captures position signals from cylinders, clamps and differential components, but also enables actuators such as air valves and solenoid valves to execute commands. It can simplify wiring, realize the system's online diagnostic function, reduce the failure rate, and facilitate subsequent inspection and maintenance.

Used for roller conveyors in logistics systems to trigger and stop roller conveyor motors. Offline testing can speed up troubleshooting, reduce the overall cost of smaller PLCs, and shorten response times.

SVLEC IO -Link technology devices implement the "last few feet" technology standard from the communication network to the field. To meet the requirements of more types of sensors and higher flexibility in the production process of modern intelligent enterprises, it also saves money for enterprises.

Save money by installing IO -Link communication devices

Paired with extremely cost-effective input/output hubs, up to 256 input or 312 output signals can now be processed very efficiently. This results in cost savings of 15% to 20% per input compared to standard fieldbus modules.

M12 connection cable can be used to connect a sensor/sensor hub, so overall savings can rise as high as 30% to 40%, including eliminating fieldbus and power lines. Our Connector technology includes Connector, Heavy Duty Connector, cables, etc., which can also be adapted to io link modules.In addition, the sensor hub requires only one bus address to flexibly detect sensor signals within a range of 20 m, ensuring extremely high efficiency.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.